¿Hablamos?

¿Tienes alguna duda? ¡Consúltanos! Intentaremos aclarar tus dudas lo antes posible, normalmente en menos de 24 horas. Si lo prefieres, puedes llamarnos al 943 311 455

INFORMACIÓN SOBRE PROTECCIÓN DE DATOS

Responsable: Zucchetti Software Spain S.L.U.

Finalidad: Tratamos sus datos personales para la gestión y atención a clientes y personas interesadas en productos y servicios de Zucchetti Software Spain S.L.U. y envío de newsletter.

Legitimación: Consentimiento e interés legítimo.

Destinatarios: Los datos no serán objeto de comunicación a terceros salvo en caso de ser necesario para el cumplimiento de obligaciones legales o para dar soporte al servicio.

Derechos: Acceder, rectificar y suprimir los datos, así como otros derechos, como se explica en la información adicional.

Información adicional: Puede accederse a la información adicional sobre el tratamiento de sus datos personales en el siguiente hipervínculo.

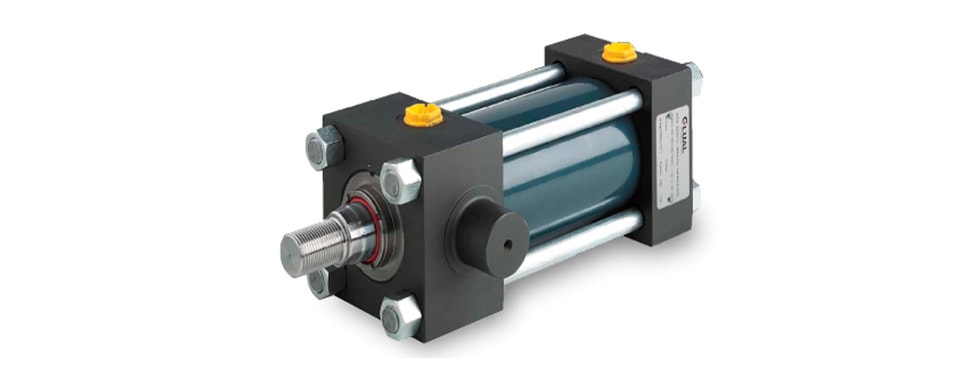

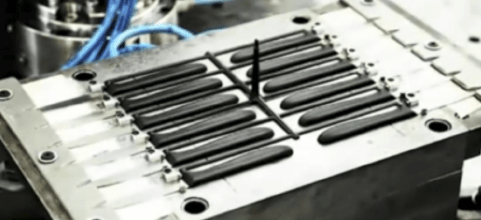

FABRICACIÓN DISCRETA

FABRICACIÓN DISCRETA FABRICANTES DE COMPONENTES DE AUTOMOCIÓN

FABRICANTES DE COMPONENTES DE AUTOMOCIÓN PROYECTOS

PROYECTOS DISTRIBUCIÓN

DISTRIBUCIÓN SERVICIOS

SERVICIOS SANIDAD

SANIDAD ALIMENTACIÓN

ALIMENTACIÓN GRAN CONSUMO

GRAN CONSUMO